SIA «BELIMPEKS» offers a full profile covering for railway and tramcar track crossings made of a composite materials. The covering is designed for leveling of automobile and railway roads. The covering cushions shock load on the rails caused by the moving transport, carries water outside the railway at the level crossing section, distributes wheel load, safes width of a rail track. In urban areas the covering reduces noise level both in business quarters and residential areas. On moving of transport with turn and acceleration the relief surface of a covering creates a good skidding resistance.

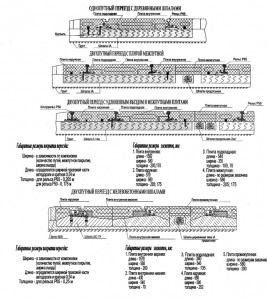

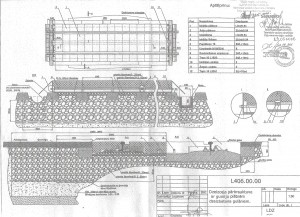

This covering is used on railway tracks with 1520 mm and 1435 mm gauge, with rails of types: P65, UIC60, P50, with new or used wooden sleepers of 1(1A) type with DO-type bracing, or with concrete sleepers of types: ШС-1У, SVITRAK, DG-SKL-14, B91S/1 with КБ-type bracings (sleepers epure 1840 pc/km, distance between sleepers axes 540 mm).

In case of covering of the concrete sleepers of types DG-SKL-14, SVITRAK and B91S/1 the outer edges of cover panels are bordered with concrete borders of 250х300 mm section and 2016 mm length or of 1008 mm length on a radius tracks. The borders are to be fixed on a concrete base. Top edges of the concrete borders are to be overlaid with 4-7 cm deep asphalt layer.

Track spacing panels are produced upon customer’s request.

Performance characteristics:

- Surface of the rubber plates is resistant to salt, oil and other specific for roads kinds of dirtiness as well as to climate effects such as sunlight and frost, and its operating temperature interval is from -40˚С to +60˚С.

- Rubber plate covering is wear-resistant and high load-proof in circumstances of intensive traffic. Carrying capacity limit of car axial load is min 11,5t.

- Rubber covering has a grooved surface for the purpose of providing anti-skidd effect. Adhesive coefficient between car weel and rubber covering surface is min 0,5.

- The material of rubber plates provides electrical isolation of rails.

- Rubber plates are designed to be installed and deinstalled easy and quickly.

- Design of pieces provides damage protection to the edges of crossing. Edges of crossing have a joining elements – concrete borders.

- Service life of rubber cover panels – 15 years.

- Guarantee period of production – 5 years.

Level crossing systems are installed both on straight sections of railway track and on radius tracks and switches. Installation in variable sized track spacing of multi-track crossings is also possible.

For manufacturing and installing of level crossing panels on radius tracks, switches and in track spacing an engineering documentation is made for every concrete level crossing system. Installation directions are enclosed.

At the customer’s request contract supervisison can be made.

SIA «BELIMPEKS» reserves the right to make changes resulting in improvement of technical properties of the product.

|

|

|

Structure of the level crossing on ralway track with wooden sleepers:

| 1. | Inner panel | L/540 pc. |

| 2. | Outer panel | 2L/540 pc. |

| 3. | Sole panel | 2L/540 pc. |

| 4. | Stop square | 2 pc. |

| 5. | Spike | 2L/540+2 pc. |

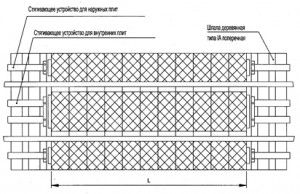

| 6. | Tightening device for inner panels | 2 pc. |

| 7. | Tightening device for outer panels | 4 pc. |

Structure of the level crossing on ralway track with concrete sleepers:

| 1. | Top inner panel | L/540 pc. |

| 2. | Lower inner panel | 2L/540 pc. |

| 3. | Sole panel | 2L/540 pc. |

| 4. | Sole panel | 2L/540 pc. |

| 5. | Tightening device for inner panels | 2 pc. |

| 6. | Tightening device for outer panels | 2 pc. |

*Note: L – width of the roadway in mm.

Rubber coverings for railway level crossings are made of compounded rubber which guarantees following stress-strain properties of the material:

| Lower layer of railway crossing: | |||

| Properties | Standards | Standard values | Producer’s guaranteed values |

| Shore number А | DIN 53505 | 70±5 | 70±5 |

| Density | DIN 53479 | 1,15±0,015g/cm3 | 1,15±0,015g/cm3 |

| Tensile Strength | DIN 53504 | ≥2.0МПа | ≥2.0МПа |

| Extension to breaking | DIN53504 | ≥40% | ≥60% |

| Relative resistance | IEC 93 | ≥1,0х106ом | ≥1,0х106ом |

| Top layer of railway crossing: | |||

| Properties | Standards | Standard values | Producer’s guaranteed values |

| Shore number А | DIN 53505 | 67±5 | 67±5 |

| Density | DIN 53479 | 1,15±0,015g/cm3 | 1,15±0,015g/cm3 |

| Tensile Strength | DIN 53504 | ≥10МПа | ≥10МПа |

| Extension to breaking | DIN53504 | ≥100% | ≥350% |

| Relative resistance | IEC 93 | ≥1,0х106ом | ≥1,0х106ом |

| Abrasion resistance | DIN 53516 | ≥60mm3/Дж | ≥60mm3/Дж |

| Adhesion coefficient in high humidity | DIN NE 9001-14001; Акт БГТУ | ≥0,48 | ≥0,50 |